MACHINE GUNS

BREN L4 Light Machine Gun

| Calibre: | 7.62mm | Muzzle Velocity: | 838m/s |

| Weight: | 8.68kg | Length: | 1.156m |

| Magazine Capacity: | 30 rounds | Rate of Fire: | 40 rounds/min |

| Effective Range: | 600+m | Date in Service: | 1954 |

In August 1934, after a 50000-round endurance test, the BRNO ZGB 34 LMG was adopted by the British Armed Forces. The licensing arrangements with Ceskoslovenska Zbrojevka Brno permitted the manufacture of a new gun, designated as BREN (for Brno and Enfield), at Royal Small Arms factory in Enfield. the first Bren Mark 1 light machine gun, left the Enfield factory in September 1937.

During WW2, Bren guns were also made in Canada, by John Inglis Co., and in Australia, by Lithgow Small Arms factory. The Bren machine guns proved to be highly effective, reliable and very accurate weapons, but the Bren guns were gradually simplified and lightened, resulting in a series of Marks, from Mk 1 to Mk 4. At the same time, the Inglis Company, in Canada produced a number of Bren guns in 7,92 Mauser calibre for China.

When Britain has jointed the NATO in 1954, it solved the problem of the light machine gun in new standard caliber (7,62x51mmNATO)by simple adaption of the Bren to the new cartridge. These "NATO standard" Bren guns received official index L4A1, which went through a number of modifications during it's service in the British Armed Forces, the final model produced being the L4A9.

BREN Light Machine Gun Variants:

BREN Mk.1:...... Original version with radial type sight, and additional grip under the butt (not present on latter marks).

BREN Mk.1(M):. Canadian-made version, with simplified non-telescoping bipod legs and simplified butt without shoulder rest and buttplate buffer; also was made in 7,92x57 calibre for China.

BREN Mk.2:..... Simplified war-time version with simplified rear sight.

BREN Mk.3:..... Lightened version of the Mk.2, with barrel shortened by 70mm (2¾inch).

BREN Mk.4:..... Minor variation of previous mark, with different butt shape.

BREN L4A1:......Bren Mk.3 guns converted to 7,62x51 NATO ammunition using Canadian-made7,92x57 bolts (Chinese contract) and new barrels and magazines; each gun was issued with two barrels.

BREN L4A2:..... Same as L4A1 but with lighter bipod.

BREN L4A3:..... Bren Mk.2 converted to 7,62x51 NATO the same way as L4A1.

BREN L4A4:..... Similar to L4A1 but barrel is chrome-lined; only one barrel was issued per gun (no spare barrels at unit level).

BREN L4A5:..... Same as L4A3 but with chrome-lined barrels. Issue was limited to British Navy.

BREN L4A6:..... L4A1 re-issued with chrome-lined barrel.

BREN L4A7:..... Conversion of Bren Mk.1 to 7,62x51, proposed for Indian army; Not produced.

BREN L4A8:..... Not produced.

BREN L4A9:..... L4A4 modified with addition of the sight bracket for AA or Night/IR sighting equipment.

BREN Mk1

BREN Mk2

BREN Mk3

BREN L4

Manufacturers Stamps:

| CODE | MANUFACTURER |

| D/E (E inside D): | Enfield RSAF |

| M67: | Monotype |

| D: | Daimler |

| Inglis: | Canadian |

| Lithgow: | Australian |

| SAF: | Indian Small Arms Factory |

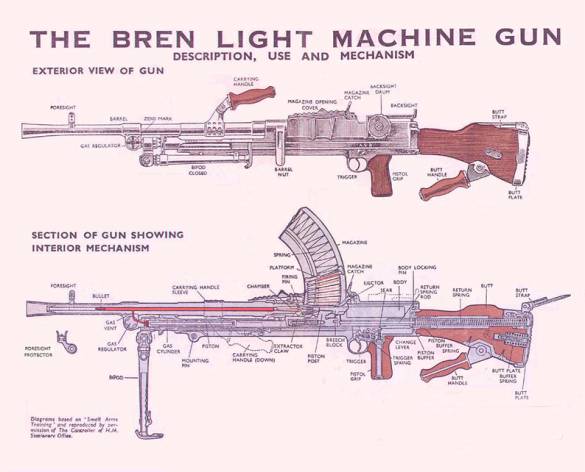

The L4 BREN LMG is a gas-operated, air cooled, selectively fired machine gun. It has a quick-detachable barrel

The action of gun is powered by a long-stroke gas piston, located below the barrel.

The ammunition feed is from top-mounted box magazines. These are made from sheet steel and hold 30 rounds in a

two-row configuration (although in the field soldiers preferred to load only 27-28 rounds to reduce strain on

the magazine spring and thus ensure reliability of the feed under harsh conditions).

The magazine housing has a sliding dust cover which is slid forward to load the gun. Spent cartridges are

ejected downwards. The ejection port is normally closed with its own dust cover which opens automatically

once the trigger is pressed.

The trigger unit permits both single shots and automatic fire, selectable through a safety / fire mode selector lever

situated at the left side of the pistol grip.

L86A2 Light Support Weapon

| Calibre: | 5.56mm | Muzzle Velocity: | 975m/s |

| Weight: | 6.34kg | Length: | 0.9m |

| Magazine Capacity: | 30 Round Box Magazine | Rate of Fire: | Cyclic 775 rounds/min |

| Effective Range: | 1000m | Date in Service: | 1985 |

The development of the SA-80 (Small Arms family for 1980’s) was started in Britain by the late 1960’s, with the search for the "ideal"

small-bore ammunition. By the mid-1970’s British designers developed a 4.85x49mm cartridge, intended for the SA-80 system, and consequently

designed a SA-80 IW rifle and SA-80 LSW light machine gun for this ammunition. The 4.85mm LSW appeared in the prototype form circa 1976, but

the NATO trials, held in the 1978-1979, resulted in adoption of the 5.56mm cartridge as a common, NATO ammunition, so British designers from

the RSAF Enfield redesigned their weapons for 5.56mm NATO rounds. The LSW was based on the SA-80 IW design, which is covered in the Assault

Rifles section on this site under the L85A1 topic. The final version of the SA-80 LSW, was adopted by the British Army, in 1986, and total s

lightly over the 22,000 LSW weapons were manufactured before the production of both L85 IW and L86 LSW was ceased.

The L86A1 was plagued by the same problems as its sister, L85A1 rifle. In fact, the L86A1 was more suitable as a semi-automatic Para-sniper

rifle, than the LSW / LMG, due to the poor reliability in full automatic fire, relatively small (by machine guns standards) magazine capacity

and the lack of quick detachable barrels.

L86A2

Current British troops prefer much heavier and belt-fed 7.62mm L7A1 GPMG (a license-built copy of Belgian FNMAG general purpose machine gun),

and at the present time the existing stocks of L86A1 are complemented with the 5.56mm FN Minimi belt-fed LMG in the short-barrelled Para configuration.

The L86A1 will be used mostly as a longer-range, aimed fire weapons, while the suppressive fire functions will be conducted using more effective FN Minimi.

The L86 LSW (Light Support Weapon) was developed concurrently with the L85 IW (Individual Weapon) of the British Army. Both systems were adopted as

standard issue weapons in the mid-1980’s, seeing combat actions across the 1991 Gulf War, the Balkans Wars and - more recently - in Afghanistan and

Iraq. The L86 utilises some 80% commonality of parts with the L85 assault rifle but is classified as a fire support weapon for squad-level engagements,

offering accurate, ranged voluminous fire that outmatches that of the base L85 automatic weapon.

The L86 makes use of the same 5.56x45mm NATO cartridge of the L85 and operates from the same gas system. However, to coincide with its fire support

role, the weapon is fielded with a longer, heavier barrel which increases muzzle velocity and, therefore, increases the cartridge's range and accuracy

at range for engaging targets beyond the scope of the base L85 system. The barrel is furthermore fixed and not readily changeable. The L86 also features

a rear vertical hand grip as well as a shorter hand guard with lightweight bipod. The L86 does, however, retain the magazine-fed quality of the L85 and

can accept its 30-round forms. A 60-round magazine is also available. The weapon can fire in semi-automatic mode or in full-automatic as the situation

requires - the former through a closed breech and the latter holding the bolt by a rear sear. The SUSAT (Sight Unit, Small Arm, Trilux) optic is retained

as standard.

The L86 initially debuted in the original L86A1 production form. These then gave way to the improved L86A2 variant which attempted to remedy the ongoing

issues that proved disastrous to early L85/L86 units. The mid-life upgrade was handled by Heckler & Koch and occurred in the early 2000’s.

The L86 in the squad support role has since given ground to the L110A1 (Fabrique Nationale FN Minimi), relegating the L86 to something more of a

marksman's platform.

L7 General Purpose Machine Gun

| Calibre: | 7.62mm | Muzzle Velocity: | 838m/s |

| Weight: | 10.9kg | Length: | 1.23m |

| Magazine Capacity: | Belt Feed | Rate of Fire: | Cyclic 750 rounds/min |

| Effective Range: | 800-1800m | Date in Service: | 1954 |

The MAG (Mitrailleuse d'Appui General = General Purpose Machinegun), had been developed by the famous Belgian company FN Herstal in the 1950s, as a true universal machine gun, that could be used as a light MG on bipod, as a medium MG on tripod or as a vehicle-mounted MG. The basic design of the MAG is no more than a time-proven Browning action, taken from the M1918 BAR automatic rifle, turned upside down and adopted for belt feed. The basic design used as much steel stampings and pressings as possible to save the labour and costs, and the final gun had the angular, but very business-like appearance.

L7A1/L7A2 General Purpose Machine Gun

| DESIGNATION | DESCRIPTION |

| L7A1: | 7.62×51 mm NATO FN MAG 60.20 T3 machine gun. |

| L7A2 L7A1 variant: | FN MAG 60.20 T6; Improved feed mechanism and provision for 50 round belt-box. |

| L8A1 L7A1 variant: | For mounting inside AFVs. No buttstock. Barrel fitted with fume extractor. Solenoid-triggered, but with folding pistol grip for emergency use. |

| L8A2 L8A1 variant: | Improved feed mechanism. |

| L19A1 L7A1 variant: | Extra-heavy barrel. |

| L20A1 L7A1 variant: | For remote firing in gun pods and external mountings. |

| L20A2 L20A1 variant: | Improved feed mechanism. |

| L37A1 L8A1 variant: | L8A1 breech & L7 barrel for mounting on AFVs. Conventional pistol grip and trigger, plus kit allowing dismounted use. |

| L37A2 L37A1 variant: | L8A2 based. As above. |

| L43A1 L7A1 variant: | For use as a ranging gun on the Scorpion light tank. |

| L44A1 L20A1 variant: | Royal Navy variant. |

L7A2 General Purpose Machine Gun

The L7 and the related L8 are license-built derivatives of the MAG. The official British Army designation for the current version is the L7A2 GPMG (General Purpose Machine Gun).

The L7 was adopted by the British forces as a replacement for the long-serving Vickers machine gun and the Bren in 1957.

Built under license originally by Royal Small Arms Factory, Enfield and currently by Manroy Engineering, it serves in the British Army, the Royal Marines and other services.

There have been two main variants, the L7A1 and L7A2, developed for infantry use, with the L7A2 having superseded the earlier variant. Several other variants have been developed, notably the L8 (produced in the L8A1 and L8A2 versions), modified for mounting inside armoured vehicles (the L37 variant was developed for mounting on armoured vehicles). Although intended to replace the Bren entirely, that light machine gun (redesignated the L4) continued in use, until the adoption of the L86A1 Light Support Weapon (LSW). The LSW was intended to replace both the L7 and the L4 in the light machine gun role, but sustained fire capabilities and reliability resulted in units continuing to utilize the L4 & L7 whenever possible. The British Army and Royal Marines have since been issued with the L110A1 (FN Minimi Para) to replace the LSW as the light section support or fire support weapon. This uses the same NATO-standard 5.56×45mm ammunition as the L85 assault rifle.

L7A1 General Purpose Machine Gun

In 1961, the Royal Small Arms Factory, Enfield, undertook production of the MAG in the following versions: L7A2, L8A2, L37A2, L20A1 and the L43A1, using the M13 ammunition belt.

The L7A2, GPMG, replaced the L7A1 in service with the British Army, featuring minor changes. These were, a 10-position gas regulator valve, a plastic butt-stock and a bracket, used to mount optical day/night-vision sights, mounted to the left side of the receiver. In a stationary defensive role, the L7A2 can be mounted on the L4A1 tripod in conjunction with a periscope sight.

The L8A2 coaxial tank machine gun (replacing the L8A1), has a different gas valve switch (closed, single-position), a different flash hider and a modified cocking handle. The weapon also has a trigger group that accepts electrical input and a lever in the feed tray that enables the belt to be removed without lifting the feed tray cover.

The L37A2 (replacing the L37A1), is designed to be mounted on tank turrets, in the commander's position, on wheeled armoured vehicles and on armoured personnel carriers. It differs from the L8A2, in its trigger group, which was adapted from the L7A2 GPMG. The machine gun can be used in the ground role for self-defense, by dismounted vehicle crew members, an egress kit is issued with the weapon, consisting of an L7A2 barrel, bipod and buttstock.

The L20A1 aircraft machine gun is based on the L8A2, but differs by having an electrical trigger and a slotted flash suppressor. The L20A1 can also be converted to right-hand feed.

The L43A1, also developed from the L8A2, is a coaxially-mounted tank machine gun used to sight-in the vehicle's main gun by firing ballistically-matched tracer ammunition at the target to confirm the trajectory visually. The weapon's barrel, fitted with a flash hider, has a reinforced and heavier structure that increases the weapon's accuracy especially during sustained fire.

The L7/L8 is an extremely reliable and proven design, that seen widespread service, being adopted by many armies around the world.

An inoperative, drill version was was produced designated L46A1.

Vehicle Mounted General Purpose Machine Gun

L108A1 FN Minimi Machine Gun

| Calibre: | 5.56mm | Muzzle Velocity: | 925m/s |

| Weight: | 6.85kg | Length: | 1.040m |

| Magazine Capacity: | Belt Feed | Rate of Fire: | Cyclic 900 rounds/min |

| Effective Range: | 1,000m | Date in Service: | 1990 |

The L108A1 Minimi (Mini Mitrailleuse; "mini machine gun") is a Belgian 5.56mm light machine gun developed by Fabrique Nationale (FN) in

Herstal by Ernest Vervier. First introduced in 1974, it has entered service with the armed forces of more than 45 countries. The weapon is currently

manufactured at the FN facility in Herstal and their US subsidiary FN Manufacturing LLC.

The Minimi is a light machine gun firing from an open bolt. The weapon is primarily chambered for 5.56x45mm NATO, though a 7.62×51mm NATO variant exists.

It is an air-cooled weapon, capable of fully automatic fire only. It can be belt fed or fed from a magazine.

The Minimi is configured in several variants: the Standard model as a platoon or squad support weapon, the Para version L110A2 for paratroopers and the

Vehicle model as secondary armament for fighting vehicles.

The Minimi uses a gas-actuated long-stroke piston system. The barrel is locked with a rotary bolt, equipped with two massive locking lugs, forced into

battery by a helical camming guide in the bolt carrier. Upon firing, the piston is forced to the rear by expanding propellant gases bled through a port

in the barrel near the muzzle end. The piston rod acts against the bolt carrier, which begins its rearward motion guided on two rails welded to the

receiver walls, while the bolt itself remains locked. This sequence provides a slight delay that ensures chamber pressure has dropped to a safe level

by the time a cam in the bolt carrier rotates and unlocks the bolt, increasing extraction reliability as the empty cartridge casing has had the time to

cool down and contract, exerting less friction against the chamber walls.

L110A1 FN Minimi PARA Machine Gun

The Minimi fires from an open bolt, which reduces the danger of a round cooking off after extended periods of continuous fire, since a cartridge is

only momentarily introduced into the chamber prior to ignition, and the movement of the bolt and bolt carrier forces air through the chamber and

barrel after each shot, ventilating the barrel and removing heat. Gas escaping the gas cylinder is directed upward, avoiding kicking up dust and

debris that would reveal the shooter's position.

The Minimi has a push-button type manual safety installed in the trigger housing, above the pistol grip. In the "weapon safe" position, it disables

the sear mechanism; pushing the button to the right side exposes a red-colored rim on the left side of the firearm and indicates the weapon is ready

to fire. The black polymer pistol grip from the FAL and FNC rifles was initially used, but the Minimi is currently fitted with a modified grip with

lateral grooves, installed at a smaller angle to the receiver.

The Minimi features a welded receiver made from stamped steel. Both the standard and Para variants are equipped with a fixed, folding bipod mounted to

the gas tube and stowed under the handguard. The Minimi can also be fired from the Belgian FN360° tripod or the American M122 mount using an M60 pintle.

The vehicle-mounted Minimi is fitted with an electrically powered trigger that enables it to be fired remotely from within an armoured fighting vehicle.

The standard light machine gun version has a 465mm (18.3 in) barrel and a skeletonised aluminium stock with a folding wire shoulder strap. The shortened

Para model has a 349mm (13.7 in) barrel and a collapsible metal stock, while the vehicle-mounted model has a 465mm (18.3 in) barrel but does not have a

stock or iron sights. All models can alternatively be fitted with a fixed synthetic stock, the same used on the M249, which contains a hydraulic buffer

that contributes to stabilising the rate of fire and reducing recoil forces.

The weapon is fed from the left-hand side by disintegrating-link M27 ammunition belts (a miniaturised version of the 7.62mm M13 belt), from either an

unsupported loose belt, enclosed in a polymer ammunition box with a 200-round capacity attached to the base of the receiver, or from detachable STANAG

magazines, used in other NATO 5.56mm assault rifles such as the M16 and FNC. The pawl-type feeding mechanism is modeled on the system used in the MAG

general-purpose machine gun, which was originally used in the World War II-era MG 42. The belt is moved in two stages during both the forward and rearward

movement of the reciprocating bolt carrier, which provides for a smooth and continuous feeding cycle. The feeding mechanism top cover features a device

that indicates the presence of a cartridge in the feed path.

L1A1 M2 Browning Machine Gun

| Calibre: | 12.7mm | Muzzle Velocity: | 890m/s |

| Weight: | 38kg | Length: | 1.654m |

| Magazine Capacity: | Belt Feed | Rate of Fire: | Cyclic 600 rounds/min |

| Effective Range: | 1800m | Date in Service: | 1993 |

The M2 Machine Gun or Browning .50 Calibre Machine Gun is a heavy machine gun designed towards the end of World War I by John Browning. It is very

similar in design to Browning's earlier M1919 Browning machine gun, which was chambered for the .30-06 cartridge. The M2 uses the much larger and much

more powerful .50 BMG cartridge, which was developed alongside and takes its name from the gun itself (BMG standing for Browning Machine Gun). The M2

has been referred to as "Ma Deuce", as a GI phonetic slang or "the fifty" in reference to its calibre. The design has had many specific designations;

the official designation for the current infantry type is Browning Machine Gun, Cal. .50, M2, HB, Flexible. It is effective against infantry, unarmoured

or lightly armoured vehicles and boats, light fortifications and low-flying aircraft. The M2 machine gun has been in production longer than any other

machine gun.

The Browning .50 calibre machine gun has been used extensively as a vehicle weapon and for aircraft armament by the United States from the 1930s to

the present. It was heavily used during World War II, the Korean War, the Vietnam War, the Falklands War, and during the Iraq War and War in Afghanistan

in the 2000’s and 2010’s. It is the primary heavy machine gun of NATO countries, and has been used by many other countries. The M2 has been in use longer

than any other small arm in U.S. inventory except the .45 ACP M1911 pistol, also designed by John Browning.

L1A1 M2

The current M2 is manufactured in the United States by General Dynamics and U.S. Ordnance for use by the United States government, and for U.S. Foreign

Allies via FMS sales. FN Herstal has manufactured the M2 machine gun since the 1930s.

The thicker-walled, air-cooled barrelled M2, was designated the M2 HB (HB for Heavy Barrel). The added mass and surface area of the heavy barrel

compensated somewhat for the loss of water-cooling, while reducing bulk and weight: the M2 weighs 121 lb (55 kg) with a water jacket, but the M2

HB weighs 84 lb (38 kg). Due to the long procedure for changing the barrel, an improved system was developed called QCB (quick change barrel). The

lightweight "Army/Navy" prefixed AN/M2 "light-barrel" version of the Browning M2 weighing 60 pounds (27 kg) was also developed, and became the standard

aviation machine gun of the World War II-era for American military aircraft of nearly every type.

The Browning M2 is an air-cooled, belt-fed machine gun. The M2 fires from a closed bolt, operated on the short recoil principle. The M2 fires the .50 BMG

cartridge, which offers long range, accuracy and immense stopping power.

A soldier with D Squadron the Household Calvary Regiment (HCR)

mans a L1A1 HMG mounted on a Jackal 2 patrol vehicle.

The M2 has varying cyclic rates of fire, depending on the model. The M2HB (heavy barrel) air-cooled ground gun has a cyclical rate of 450-575 rounds

per minute. The early M2 water-cooled AA guns had a cyclical rate of around 450–600 rpm. The AN/M2 aircraft gun has a cyclic rate of 750–850 rpm; this

increases to 1,200 rpm or more for AN/M3 aircraft guns fitted with electric or mechanical feed boost mechanisms. These maximum rates of fire are generally

not achieved in use, as sustained fire at that rate will wear out the bore within a few thousand rounds, necessitating replacement. In addition to full

automatic, the M2HB can be selected to fire single-shots or at less than 40 rounds per minute, or rapid fire for more than 40 rounds per minute. Slow and

rapid firing modes use 5-7 round bursts with different lengths of pause between bursts.

The M2 has an effective range of 1,830 metres (2,000 yd) and a maximum effective range of 2,000 metres (2,200 yd) when fired from the M3 tripod. In its

ground-portable, crew-served role as the M2HB, the gun itself weighs 84 pounds (38 kg) and the assembled M3 tripod another 44 pounds (20 kg). In this

configuration the V-shaped "butterfly" trigger is located at the very rear of the weapon with a "spade handle" hand-grip on either side of it and the bolt

release the center. The spade handles are gripped and the butterfly trigger is depressed with one or both thumbs. Recently new rear buffer assemblies have

used squeeze triggers mounted to the hand grips, doing away with the butterfly triggers.

Because the M2 was intentionally designed to operate in many configurations, it can be adapted to feed from the left or right side of the weapon by

exchanging the belt-holding pawls, and the front and rear cartridge stops (three-piece set to include link stripper), then reversing the bolt switch.

The operator must also convert the top-cover belt feed slide assembly from left to right hand feed as well as the spring and plunger in the feed arm.

This will take a well trained individual less than two minutes to perform.

Current ammunition types include M33 Ball (706.7 grain) for personnel and light material targets, M17 tracer, M8 API (622.5 grain), M20 API-T (619 grain),

and M962 SLAP-T. The latter ammunition along with the M903 SLAP (Saboted Light Armour Penetrator) round can perforate 1.34 inches (34 mm) of HHA

(face-hardened steel plate) at 500 metres (550 yd), 0.91 inches (23mm) at 1,200 metres (1,300 yd), and 0.75 inches (19 mm) at 1,500 metres (1,600 yd).

This is achieved by using a 0.30-inch-diameter (7.6mm) tungsten penetrator. The SLAP-T adds a tracer charge to the base of the ammunition. This ammunition

was type classified in 1993.

The Browning .50 cal HMG has been in service with the British Armed forces since 1940. The Browning M2’s currently in service with the British

Armed Forces are:

| DESIGNATION | DESCRIPTION |

| L1A1: | 12.7 × 99 mm Browning M2 machine gun |

| L2A1: | 12.7 × 99 mm Browning M2E2 machine gun |

| L6, L6A1: | 12.7 × 99 mm Browning M2HB machine gun; ranging gun for the L7 105 mm tank gun on the Centurion tank. |

| L11, L11A1: | 12.7 × 99 mm Browning M2HB machine gun; ranging gun |

| L21A1: | 12.7 × 99 mm Browning M2HB machine gun; ranging gun for the 120 mm tank gun on the Chieftain tank |

| L111A1: | 12.7 × 99 mm M2QCB machine gun |

| M3M: | 12.7 × 99 mm Browning M2HB machine gun; Upgraded M2 for use on Commando Helicopter Force and other units as helicopter door guns. |

Vehicle Mounted L1A1 HMG's, Operation Granby, Iraq 1991.