MEDIUM GIRDER BRIDGE

The Medium Girder Bridge (MGB) is a lightweight, man portable, deck type, two-girder bridging system that can be

assembled without heavy equipment. It is capable of carrying loads up to and including Main battle tanks. The MGB was

originally produced by Fairey Engineering Ltd., in Stockport England based on a design by MVEE in Christchurch.

MGBs entered service in 1971, replacing the Bailey Bridge Unit. The FEL MGB went into service with the Australian

and New Zealand army as well as the USA at about the same time.

Two MGBs are held by the Bridging Troop in the Support Squadron of a Divisional Engineer Regiment.

Single Span Bridge - 30 m long which can be built by about 25 men in 45 minutes.

Multi-Span Bridge - a combination of 26.5 m spans: a 2-span bridge will cross a 51m gap and a 3-span bridge a 76 m gap.

If necessary, MGB pontoons can be also be joined together to form a ferry.

During late 1994, a team from 35 Engineer Regiment set a new world record by building a single-storey

9-metre bridge in 10 minutes and 34 seconds.

The manufacturer Williams Fairey claims that the MGB is in service with 35 nations worldwide.

MGB is due to be replaced by the BR90 system (although some MGB will be retained for certain operational requirements).

The primary components of the MGB system are rectangular "top deck" segments, and triangular bracing "bottom deck" segments.

All segments are man portable. Short / low load bridges can be constructed using just top deck components.

Bracing with the additional lower deck dramatically strengthens the bridge allowing heavier loads and longer spans.

The segments have knuckle joints at each end; assembly consists of simply engaging the knuckle joints of adjacent

segments then inserting a pin through a hole down the length of the knuckle. In this way as many segments as are

needed are connected end to end to form a girder of the required length to span the obstruction.

Two such longitudinal girders are constructed parallel to each other to provide the bridge's strength. Deck units

are then laid between these to form a 4.0 m wide roadway.

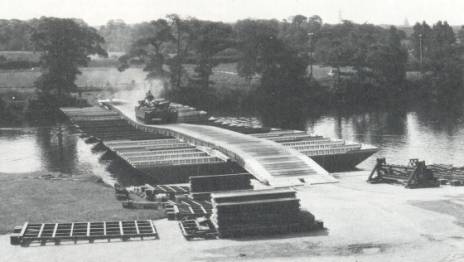

MGB Being Constructed by New Zealand Army Engineers

Componant Parts:

The MGB parts are fabricated from a specially developed zinc, magnesium, and aluminum alloy .

All componants of the MGB, with the exception of the Bankseat Beam and Junction Panels weigh under 200 kg.

Most parts can be handled easily by four soldiers. The three heavier parts, used in limited quantities, are six-man loads.

Top Panel Used to build the bridge girders. There are 7 panel points on each top panel; it is 6 ft 4 in (1.93 m) long,

2' 13/8" wide, 1' 95/8" high (1930 mm × 645 mm × 549 mm), weight 175 kg

Bay (same as above)

Bottom Panel Used as a brace for bridge girders. it is 6 ft 5 in (1.96 m) long, 2' 3" wide, 3' 73/8" high,

weight 435 lb (197 kg).

End Taper Panel Used as a bottom brace between the junction panel and bankseat beam. is 13' 25/8" long,

2'4" wide, 1'6" high, and weight 600 lb (270 kg). It is one of three components that requires 6 men to carry.

Bankseat Beam Used to keep the bridge girders properly spaced and provide connection for the ramp units.

It is one of three components that requires 6 soldiers to carry; it is 13' 31/2" long, 1' 93/8" wide, and 1 6"

high and weighs 570 lb (260 kg).

Ramps Two types US and UK ramps. UK. or short ramp is and US. or long ramps are one of three components

that requires 6 men to carry. UK ramps are 264 lb (120 kg). and the US ramp is 400 lb (180 kg).

Each type provides an approach to the bridge, 7 are required at each end. UK ramps are used for single story only.

Deck Unit 9'1" long, 1' 51/4" wide, 67/8" high, weight 163 lb (74 kg) it requires 2 soldiers to carry.

This component fills in the gap between girders. Four deck units are required per bay of bridge.

In single story construction we only use the ramp unit, bankseat beam, top panel and deck unit.

Junction Panel Used as a brace between the sloped and level part of a double story bridge.

It is 5'3/4" high, 3' 51/2" long on top, 2' 23/4" long on the bottom, 2' 11/2" wide, weight 478 lb (217 kg).

Sway Brace

Curb

Many thanks to Tony Hoare (plainmilitary@yahoo.co.uk) for the use of the following photograph:

Combat Engineers Constructing MGB on Salisbury Plain